3D design and 3D modelling

ATELIER FALHER puts its unique expertise at the service of 3D design and 3D modelling of your object, furniture, model or prototype project.

Whatever the complexity of the 3D object to be manufactured in wood, it is essential to have a perfect 3D modelling file.

We can intervene at various stages : 3D modelling from 2D drawing, 3D scan, file modification through to extraction of the flawless STL file used by the wood additive manufacturing machine tool.

contact us to create Your 3D wood project

Drawing and 3D modelling of an object

ATELIER FALHER can design your project for you in 3D digital format.

Based on your 2D drawing, our 3D designer will draw up the 3D layout.

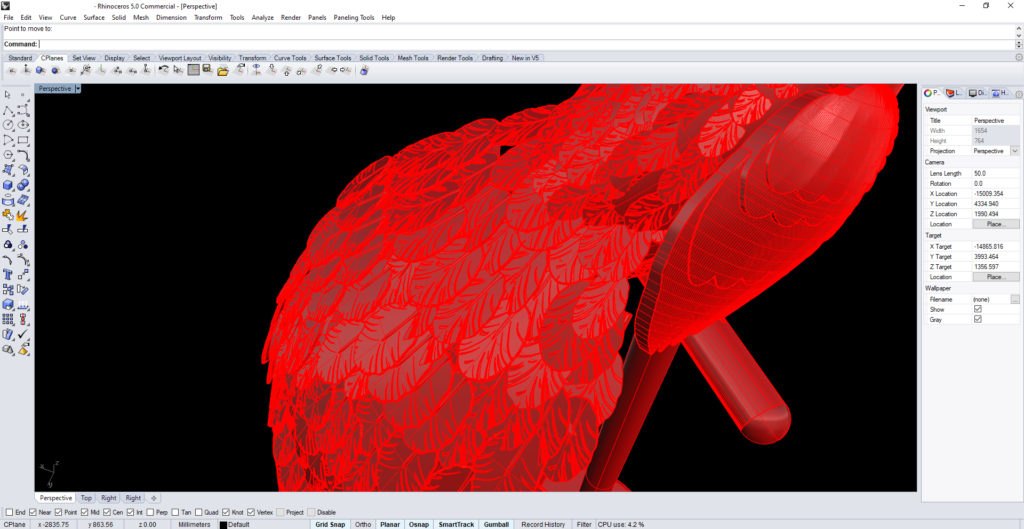

We design the virtual model of your part using Rhinocéros 3D computer-aided design software. ATELIER FALHER uses this professional software in the same way as engineers, designers and architects.

Rhinocéros 3D is a surface and parametric CAD modeller. It is widely used for creating design, digital sculpture and objects with organic shapes, etc.

The surface of the object is defined mathematically. And the software models in three dimensions and converts the 2D drawing into a volume : a complex geometric shape, a refined object, a sculpture, an architectural piece, etc.

The modelling file obtained in this way is essential for the digital control of the micro-milling tool. It is saved in the usual STL format, which translates into a language that can be understood by the additive manufacturing machine.

The 3D model data only describes the geometry of the model. It provides all the perfectly accurate information about the surface of the object. This information is required to control the wood 3D additive manufacturing machine.

3D scan of a complex object

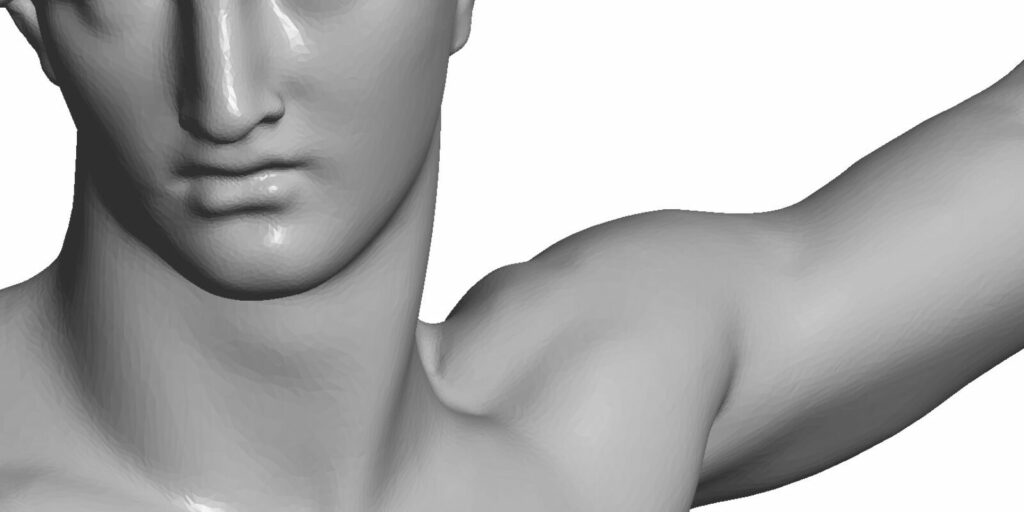

ATELIER FALHER can also use its 3D scanner to digitise a complex part to be manufactured in 3D, such as a statue, a collector’s item, etc.

We use a 3D scanner, … In this way we obtain a 3D design and 3D modelling with an extremely fine mesh. This level of precision enables ATELIER FALHER to manufacture parts with complex shapes and aesthetic rendering.

The 3D digital file resulting from the scan can then be processed and checked directly with the Rhinoceros 3D software.

The illustration shows a close-up view of the 3D digital scan we produced of the “Genius of Liberty” sculpture on display at the Louvre.

Modifying a 3D file

Our designer can also work directly on your 3D file. We clean up and refine the meshes to simulate the use of parts, particularly prototypes.

We make detailed, fine-tuned changes to the model to make it lighter, easier to assemble, or to combine very small elements…